VALUTION

search SEARCH

- VALVE PRODUCTS

HOME

VALVE PRODUCTS

제품

Control Valves

Control Valves

PD4, Angle Pattern PRDS with Pneumatic Cylinder/Hydraulic Actuators

Steam Pressure Let Down & Conditioning

Model PD4, Integrated PRDS

Valution Steam Conditioning Valve Series

Valution’s steam conditioning valve series offers an advanced Pressure Reducing and Desuperheating System (PRDS) engineered to precisely control both the pressure and temperature of high-pressure, high-temperature steam.

This solution is available in various configurations, including:

1. An integrated PRDS unit that combines both pressure and temperature control.

2. Standalone components such as a globe-type pressure reducing valve, desuperheater, and temperature control valve package.

Model PD – Integrated PRDS

The Valution Model PD integrated PRDS unit typically features an angle-style body design and incorporates flow velocity control trims to minimize noise and vibration, ensuring stable performance under extreme pressure conditions.

These valves can be equipped with Valution’s proprietary flow velocity control trims, including:

- Hani Trim (multi-hole, multi-stage)

- Breeze Trim (disc stack type)

- Cage Balanced, Cascade, and Pilot Trims

Each trim type offers selectable flow characteristics - equal percentage (EQ-%), linear, or modified percentage - to meet specific system requirements with precision.

Valution’s PRDS solutions provide a high turndown ratio, ensuring wide-range flow control.

The use of advanced multi-spring-return nozzle designs delivers exceptional atomization performance.

To enhance durability, the desuperheater section is built with a double inner wall structure, offering increased protection against internal wear or damage.

A wide range of actuator types is supported, including spring-diaphragm, cylinder, electric motor, and hydraulic actuators.

In addition, the valves are fully compatible with standard E/P positioners, as well as smart and HART communication protocols, enabling advanced control and diagnostics capabilities.

PD4, Angle Pattern PRDS with Pneumatic Diaphragm Actuator

PD, Model Selection & Numbering System

- V10

- -

- PD

- 4

- 4

- 3

- 2

| Actuator Type | Model | Body Type | Trim Type | Flow Characteristics | Plug Type |

|---|---|---|---|---|---|

| V10. Spring Diaphragm V20. Spring Cylinder V30. Cylinder Double Acting V90. Electric Motor V91. Hydraulic V01. Other Type |

PD | 4. Angle Pattern 9. Custom Pattern |

0. Undefined 1. Un-balanced 2. Conven. Cage 3. Hani, 1-stage (Multi-hole) 4. Hani, 2-stage 7. Breeze Trim (Disk Stack) 9. Custom Trim |

0. Undefined 1. Linear 2. Equal % 3. Modified % 4. Quick Open 9. Custom Char. |

0. Undefined 1. Contoured 2. Cylindrical 3. Pilot 4. Cascade 5. Micro Cv 6. V-port 9. Custom |

*B : Bellows Bonnet

PD, Product Range

| Size Range | 2" - 24" (other sizes are available) |

|---|---|

| Pressure Range | ASME 300# -4500# |

| Temperature Range | -50 - 598 °C according to the material spec. |

| Body Materials | A217 WC6, WC9, C12, CA15 A351 CF8, CF8M, CF3M A182 F11, F22, F51, F91 & others |

| Trim Materials | 316, 316L, 317L, 403, 410, 420(2), 440, 630SST A182 F11, F22, F51, F91, Inconel & others |

| Trim Design | Un-balanced, Cage-balanced, Pilot-cage Disk-stack type and others |

| Trim Characteristics | E-Q%, Modified %, Linear, Quick-open, others |

| Cv Ratio | 50: 1(standard) |

| Seat Leakage Class | ANSI/FCI 70-2, Class IV, V according to the spec. |

| Applicable Actuators | Pneumatic Diaphragm, Cylinder, Electric Motor, others |

| Applicable Instruments | P/P & E/P & Smart Positioners, SOV & other Relays |

| Options | Handwheel, Limit Stopper, Special NDT |

PCV, GL2 Hani-2 trim Globe with V30 Actuator

Standalone Globe-Type PCV(GL), Desuperheater(DH), and TCV(GL) Package

Standalone PCV & TCV – Model GL

Valution’s standalone pressure reducing valve(PCV) and temperature control valve(TCV) are typically designed with a globe-style body, incorporating flow velocity control trims to reduce noise and vibration, ensuring stable operation under extreme pressure conditions.

These valves can be equipped with Valution’s proprietary trim designs, including:

- Hani Trim(multi-hole, multi-stage)

- Breeze Trim(disc stack type)

- Cage Balanced, Cascade, and Pilot Trims

Each trim type supports selectable flow characteristics - equal percentage(EQ-%), linear, or modified percentage—allowing for precise customization to meet specific system demands.

A wide variety of actuator types are supported, including spring-diaphragm, cylinder, electric motor, hydraulic.

Additionally, the valves are compatible with standard E/P positioners as well as smart and HART communication protocols, offering advanced control and diagnostics functionality.

Standalone Desuperheater – Model DH

Valution’s standalone desuperheater(DH) solution delivers a high turndown ratio for wide-range flow control, and provides superior atomization performance through its orifice-type multi-nozzle design and advanced multi-spring-return nozzle configuration.

The DH model is available in both direct-mounted and remotely installed configurations with the TCV. The illustration below depicts the remote installation type.

For enhanced durability, the desuperheater section can be optionally equipped with a double inner wall, providing extra protection against internal erosion and wear.

TCV, GL1 Cascade trim Globe with V10 Actuator

GL Model, Product Range for PCV & TCV

| Size Range | 1” ~ 24” (depends on body type & other sizes are available) |

|---|---|

| Pressure Range | ASME 150#~4500# |

| Temperature Range | -196 ~ 593 ℃ according to tde material spec. |

| Body Materials | A216 WCB, A217 WC6, WC9 A351 CF8, CF8M, CF3M A182 F51, F91, Inconel, Titanium, Lined(ETFE,PTFE,PFA), otders |

| Trim Materials | 304, 316, 316L, 317L, 403, 410, 420(J2), 440, 630SS Inconel, W-Co overlay, Titanium, otders |

| Trim Design | Contoured, Conventional Cage, Multi-hole, Multi-stage Cage, Disk-stack type and otders |

| Trim Characteristics | E-Q%, Modified%, Linear, Quick-open, otders |

| Seat Leakage Class | ANSI/FCI 70-2, Class II, VI, V, VI according to tde spec. |

| Applicable Actuators | Pneumatic Diaphragm, Cylinder, Electric Motor, Hydraulic, otders |

| Applicable Instruments | P/P & E/P & Smart Positioners, SOV & otder Relays |

| Options | Handwheel, Limit Stopper, Bellows Bonnet, Special NDT |

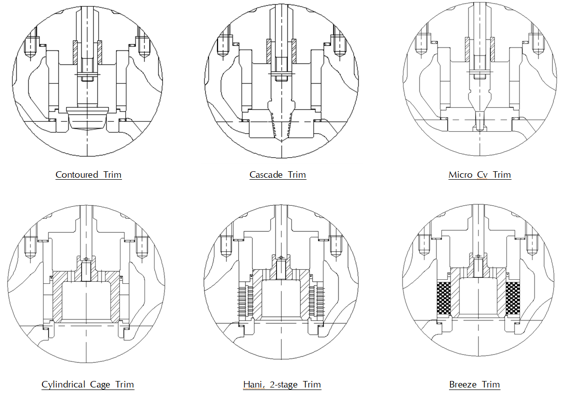

GL Model, Trim Design

DH, Standalone Desuperheater

DH Model, Product Range

| Size Range | 2" - 40" (other sizes are available) |

|---|---|

| Pressure Range | ASME 150# -1500# |

| Temperature Range | -50 - 598 °C according to the material spec. |

| Body Materials | A106 Gr-B, A335-P11, P51, P91, A105, A182 F11, F22, F51, F91 and others |

| Trim Materials | 316, 316L, 317L, 403, 410, 420(2), 440, 630SST A182 F11, F22, F51, F91, Inconel & others |

| Trim Design | Single & Multi Conical Spring Loaded Conical Type and others |

| Trim Characteristics | E-Q%, Modified %, Linear, Quick-open, others |

| Cv Ratio | 50: 1(standard) |

| Seat Leakage Class | ANSI/FCI 70-2, Class IV, V according to the spec. |

| Applicable Actuators | Pneumatic Diaphragm, Cylinder, Electric Motor, others |

| Applicable Instruments | P/P & E/P & Smart Positioners, SOV & other Relays |

| Options | Handwheel, Limit Stopper, Special NDT |