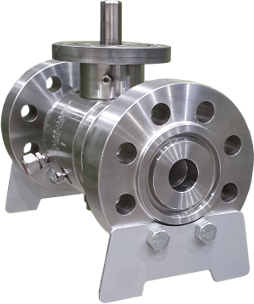

Trunnion Ball Control Valve

Valuation model TB Series is a traditional concentric trunnion type ball valve. The center of the body/seat and the center of the valve ball/Stem are concentric, so when the valve stem rotates, the ball surface and the seat surface rotate in contact, so that it is not modulating for fine and precision control, it is a ball control valve used primarily for blocking on-off. In particular, it is recommended to use the ball in a large sizes, high-pressure range, since it is a type of ball rotating with the full alignment performed by the trunnion construction.

- Traunion mounted ball : side thrust is guaranteed by the pressure of the line being absorbed into the support bearing.

- Bottom Trunnion Design : minimizes working torque and prevents particle concentration between the ball and trunnion which can interfere with ball movement

- Anti-static device: ensuring electrical continuity between the ball and other devices.

- Seat &Seal Selection: provide the most suitable material according to temperature and pressure according to the requirements of the customer's fluid services.

- Overlay Availability: seat and ball surfaces to ensure longer life of the valve.

- Replacement seat inserts: Optimized design for more cost-effective spare parts exchange.

Depending on the characteristics of the complete round ball, the flow characteristics are basically quick open properties as standard, and modulating control by the positioner can be step motion, so it is better to avoid as much as possible. According to the required seat tightness, it is also possible to apply metal or soft seat and to support the fulfillment of the leakage class VI, V, and VI.The body has a straight shape structure, which has low fluid resistance and enough space around the trim. This model can apply usally rack & pinnion cylinder, scotch yoke cylinder and electric motor type actuators. It mainly performs on-off functions with traditional SOV and Lim. S/Ws.

| Size Range | 1” ~ 20” (other sizes are available) |

|---|---|

| Pressure Range | ASME 150#~2500# |

| Temperature Range | -40 ~ 350 ℃ (according to the material spec.) |

| Body Materials | 304, 316(L), 317(L), Inconel, Titanium, others |

| Trim Materials | Ball : 316, 316L, 317L, Inconel, W-Co. overay, other coatings Seat : PTFE, RTFE, GTFE, PEEK, 316(L)+W-Co and others |

| Trim Design | Trunnion Ball type |

| Trim Characteristics | Quick open |

| Seat Leakage Class | ANSI/FCI 70-2, Class VI, V, VI according to the spec. |

| Applicable Actuators | Pneumatic Cylinder, Electric Motor, others |

| Applicable Instruments | P/P & E/P & Smart Positioners, SOV, Lim. S/W & other Relays |

| Options | Handwheel, Limit Stopper, Special NDT |