R & D Capabilities

1. Engineering-Driven Innovation

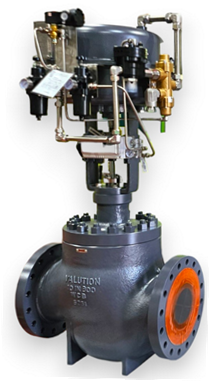

Valution’s R&D team develops next-generation valve technologies by combining extensive field experience with advanced academic expertise. We are committed to enhancing performance, reliability, and environmental safety across the industries our customers operate in.

2. Comprehensive Design & Development

From mechanical design, flow analysis, and sizing, material selection and performance testing, we handle the entire process in-house or in collaboration with trusted technical institutions—enabling fast, flexible, and fully customized solutions.

3. Customer-Oriented, Problem-Solving R&D

Valution’s research starts with real-world challenges at customer sites.

We provide precise, engineering-based solutions to recurring issues such as leakage, vibration, cavitation, and control accuracy degradation through continuous design refinement and technical innovation.

4. Talent-Driven Technical Growth

Our R&D is led by senior engineers with over 40 years of experience, working alongside a new generation of highly educated professionals. This synergy between experience and innovation fuels our unique technological competitiveness.

1. Registration Date: February 16, 2024.

2. Related Technical Description

In a control valve, the flow rate characteristics and the rated capacity coefficient are directly related to the performance of the control valve.

This technology modulates the trim of the control valve for each section and measures the flow rate and integrates it to calculate the flow rate characteristics and rated capacity coefficient of the control valve.

1. Date of registration: June 11, 2020.

2. Related Technical Description

In the application of the control valve, in compressible or incompressible fluids, when the flow rate increases beyond the prescribed range, choke phenomena and noise, vibration, and cavitation occur.

This technology controls the flow rate by forming a radial flow path structure using a disk stack within a limited space of the control valve body used at high differential pressure to implement the maximum labyrinthine multi-stage structure.

1. Registration date: January 29, 2019.

2. Related Technical Description

In the application of the control valve, pilot trim is generally applied when it

is a high-pressure operating condition and is required by Seat tightness class

At this time, during actual use, rotational force occurs between the Main Plug and the Pilot Plug, and the Valve Stem is often sheared.

This technology binds the Main Plug and Pilot Plug so that the Valve Plug & Stem does not rotate abnormally and the Valve Stem does not shear.

1. Registration date: October 10, 2023.

2. Related Technical Description

Guide Vane Actuator, which regulates the amount of compressed air in industrial turbo-compressor, requires high precision.

Most of the PIDs are remotely controlled through air pressure and electric drivers, where Handle the pneumatic actuator and the control device using the

electric/pneumatic positioner (E/P positioner).

The E/P Positioner moves the driver by converting the 4-20 mA current signal(input signal), which is a control signal, into pneumatic pressure, and also

detects the movement of the driver (Feedback Lever & Bar) to maintain balance.

This technology is a technology that modulates the detection and balance of the driver and tunes easily and quickly.

1. Registration date: July 2, 2024.

2. Related Technical Description

The Trim of the control valve uses a soft seat when the seat leakage grade requires Class VI while frequently stroking on-off and modulating, especially in the PSA process.

This technology is designed to replace the non-metal soft sheet with the metal valve plug.

1. Registration date: February 28, 2024.

2. Related Technical Description

A typical concentric ball valve cannot perform smooth stroking due to high torques in the seat when the stem rotates, and cannot cope with small signal fluctuations.

Accordingly, the segment ball valve is applied to the control valve, but the above problem cannot be completely solved if the concentric ball valve is used.

This technology is designed to have the function of an eccentric half-ball valve by applying an eccentric ball and a seat to the concentric body.